Slot Die Coating (Extrusion Coating) Technology

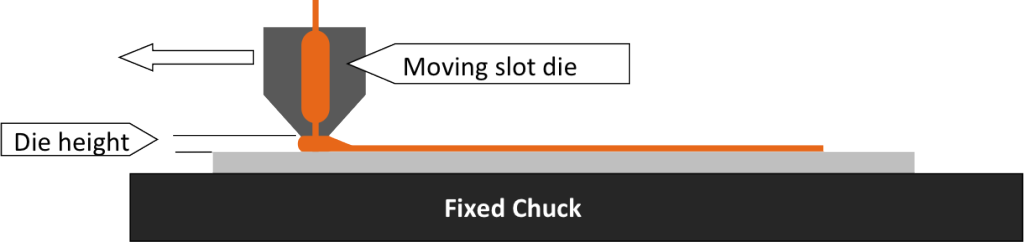

Slot die coating technology is used to deposit a variety of liquid chemistries onto glass, stainless steel, and plastic substrates for the development and production of a broad range of applications. This is achieved through the precise metering the process fluid and dispensing it at a controlled rate while the coating die is precisely moved relative to the substrate

nTact’s Slot Die Coating systems and technology allows for efficient, high performance spinless coating for applications such as flat panel displays (including LCD, OLED, flexible, and others), photovoltaic panels (such as CIGS, CdTe, OPV, and others), Solid State Lighting (OLED and LED), and various Organic and Printed Electronic applications such as RFID, Polymer Batteries, Sensors and others.

Advantages and features of nTact’s Slot Die Coating Technology include:

- Able to Coat Organic or Inorganic Liquids on flexible or rigid substrates

- Excellent coating uniformity (typically ±3% or better)

- Capable of coating a wide range of process materials: high and low viscosity fluids

- Deposit a wide range of thicknesses: from 20nm to >150μm

- High efficiency / high material utilization: typically 95% process material utilization

- Technology proven scalable from small R&D to large panel, high volume/mass production

- Systems available from R&D to large systems for production of panels over 2,000mm wide

- Highly reliable and robust process: up to 95% yields in high volume production environments

- High throughput (low TACT) processing

- Size of the system footprint is relatively small compared to competing technology platforms

- Technology applicable to roll-to-roll processing

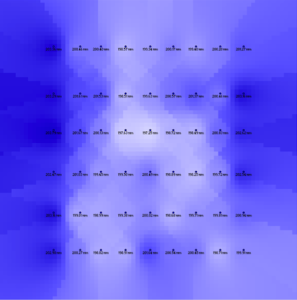

Film Thickness Uniformity of Slot Die Coated HIL

Coated with nTact Coating System

200nm HIL, 1.6% Uniformity on 6×6” substrates*

* Optimized process and HIL formulation