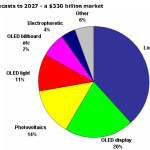

According to IDTechEx, the market for organic and printed electronics, including organics, inorganics and composites, will grow to $48.2 billion in 2017. It is estimated that by 2007, 31.6% of electronics were already being fully or partially printed. By 2017, this is estimated to rise substantially to 90.3% utilizing printing and coating methods such as slot die coating or ink jet printing.

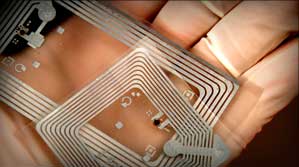

Companies are diligently working to mass produce products made of flexible, resistant and lower cost materials. A new generation of products including flat panel displays, OLED lighting, RFIDs, flexible batteries and Organic Thin Film Transistors (OTFT) are being produced on flexible plastics such as polyethylene (PET and PEN) as well as stainless steel (SST) and other metal foils. These new flexible electronics products offer features which have never before been available to the public, such as bendable and impact resistant flat panel screens and lighting capable of conforming to almost any shape.

nTact is taking a prominent role in these developments, providing systems and technology used in the development of a variety of organic and printed electronics products and technologies.