nTact has extensive in-house process development capabilities and experienced personnel to demonstrate proof of concept and feasibility of nTact’s slot die coating technology before making large capital equipment investment commitments.

Cleanroom

- Cleanroom: Certified Class 100 / Operated at Class 1,000

- Facilities Available: solvent exhaust, CDA, nitrogen, vacuum, high vacuum

Available Equipment

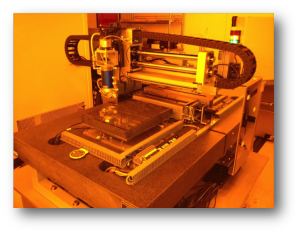

- nDeavor 2 Extrusion Coating System – Gen 2 system with maximum substrate size 400 x 500

- Atmospheric Pressure Plasma System – for cleaning and hydrophilic surface treatment

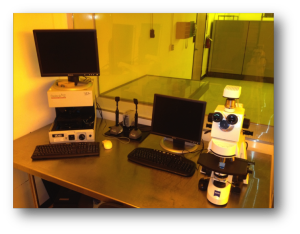

- Filmetrics Reflectometer for thin film measurement

- Dektac Profilometer

- Zeiss Axioskop2 MAT Microscope

- Gen 2 Hotplate, Gen 6 Hotplate

- Heraeus Vacuum oven

- UV ozone system

- UV exposure lamp

- Wet bench with ultrasonic bath

- General lab equipment (heated s%rrers, scales, glassware, etc.)

Process Capabilities

Slot Die Coating

- Rigid or flexible substrates, up to 400 x 500mm; wafer coating also available

- Organic solvent, aqueous or UV resin coating capability

- Dry film thickness from less than 10nm to over 100µm

Substrate Cleaning and Surface Preparation

- Atmospheric Plasma (for cleaning and hydrophilic surface treatment)

- Solvent bath

- UV Ozone

Post Coat Treatment

Post Coat Treatment

- Vacuum dry

- Hotplate bake (atmospheric, up to 200C)

- Oven bake – heated shelf type (atmospheric, inert, vacuum, up to 325C)

- UV cure

Metrology

- Filmetrics Reflectometer for thin film measurement

- Dektac Profilometer

- Zeiss Axioskop2 MAT Microscope