The slot die is one of the most critical and expensive components of a slot die coating system. It is important that the die is treated with extreme care and caution in order to avoid accidental damage that could cost several thousands of dollars and weeks to repair. nTact’s 25 years of experience in the business has helped the company fully understand the challenges involved with slot die coating, not only from a systems and process development standpoint, but also from a service and maintenance perspective. nTact offers die handling features for both production and R&D level systems..

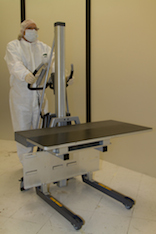

The biggest challenge with handling the die of a production level system is typically the weight accompanying the sheer mass of this stainless steel component. A Gen2 die with a coating width of 370mm can weight as much as 90lbs, while a 750mm Gen 4 die can easily weight around 160lbs. While this weight may be manageable for some folks, handling a component that size can not only be extremely difficult, but also pose a significant safety hazard, particularly when you consider some of the die lips can have extremely sharp lip edges. In order to minimize the muscle strength needed to manage the weight of the die, nTact nDeavor production systems are offered with an optional Die Maintenance Cart (DMC), which uses a hydraulic lift mechanism to transport the die from the system to a safe maintenance area. The DMC comes with a very flat granite stage which is not only used to support the die as it is lowered from the system, but also serves as an ideal surface for die maintenance. The surface is large enough to allow the operator to fully disassemble the die and perform a typical die maintenance routine.

The biggest challenge with handling the die of a production level system is typically the weight accompanying the sheer mass of this stainless steel component. A Gen2 die with a coating width of 370mm can weight as much as 90lbs, while a 750mm Gen 4 die can easily weight around 160lbs. While this weight may be manageable for some folks, handling a component that size can not only be extremely difficult, but also pose a significant safety hazard, particularly when you consider some of the die lips can have extremely sharp lip edges. In order to minimize the muscle strength needed to manage the weight of the die, nTact nDeavor production systems are offered with an optional Die Maintenance Cart (DMC), which uses a hydraulic lift mechanism to transport the die from the system to a safe maintenance area. The DMC comes with a very flat granite stage which is not only used to support the die as it is lowered from the system, but also serves as an ideal surface for die maintenance. The surface is large enough to allow the operator to fully disassemble the die and perform a typical die maintenance routine.

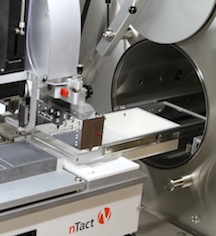

While the mass of the die is typically not as big of a factor for nTact’s smaller, stand-alone nRad R&D tools it can still pose a challenge when handling the system and die integrated in an inert gas glovebox. nTact , the innovation leader in slot die coating systems, and its partner MBraun, the leader in inert gas systems, have worked together to ensure nTact’s slot die coaters can be used as seamless as possible within a glovebox. Various features have been designed into the slot die system and MBraun’s glovebox to ensure full process compatibility. One of these features which is standard with the nRad’s inert gas option is the Die Handling System. This feature allows you to slide the die out from a load-locked antechamber, directly to the nRad’s slot die mounting station, without ever having to manually lift the die. While the dies for these R&D system weighs significantly less than the larger production system dies, even handling 15kg within an inert environment using rubber gloves and working with stretched out arms can be problematic and lead to injury.

For more information and details regarding some of nTact’s unique system features, please contact an nTact representative.